"Dauerhafte und erfolgreiche Zusammenarbeit mit zufriedenen Kunden durch modernes, zukunftsorientiertes und innovatives Denken und Handeln."

- Ingo Rathmann -

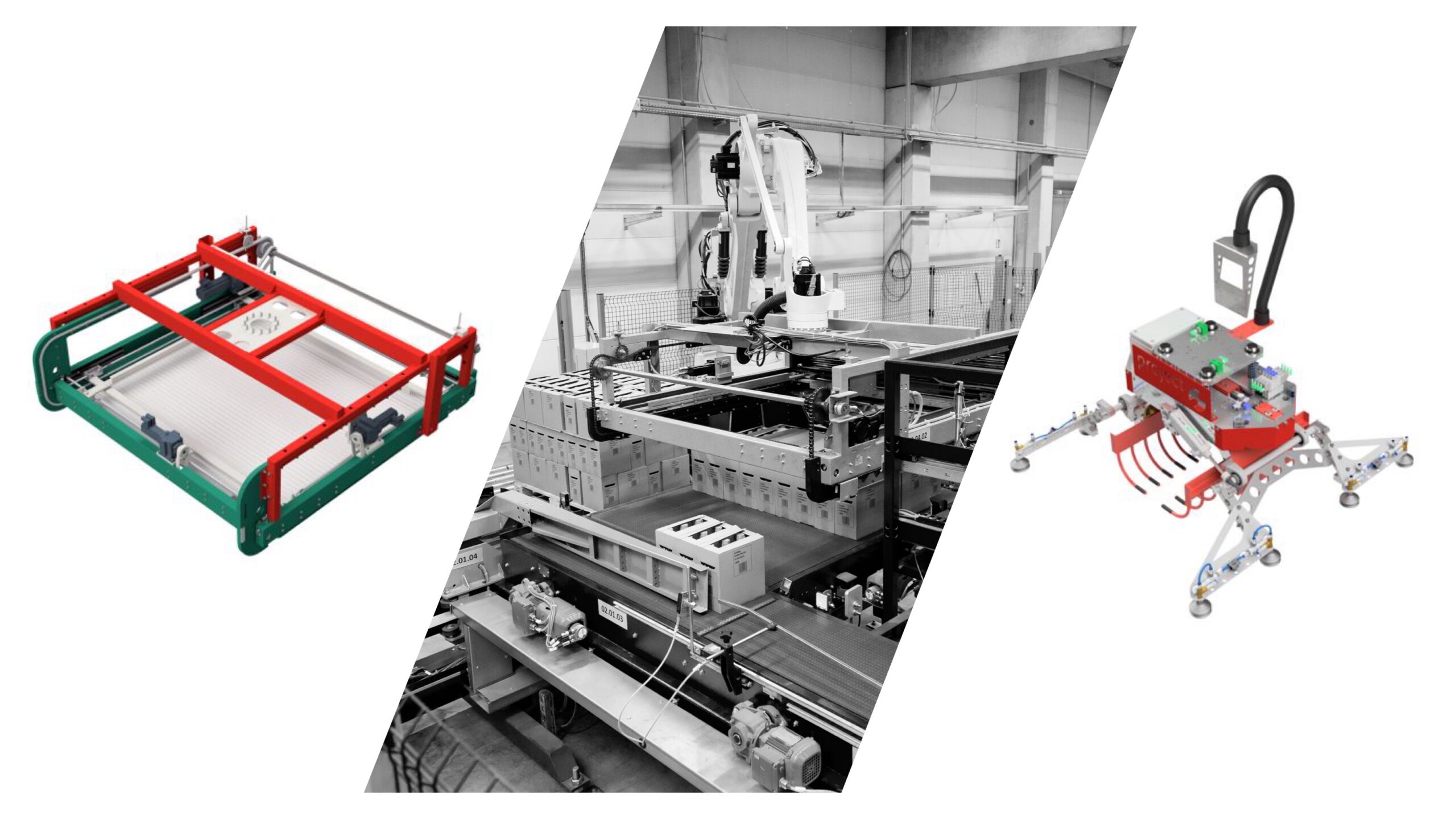

Whether you are dealing with paint rollers or bags with adhesive, fertiliser or cement, you really need to “get a grip” when it comes to final packaging. “Standard grippers for things like clamping and suctioning are not very spectacular. Adapted gripper systems are much more impressive and really spice up many automated solutions”, says Holger Hoffrichter, Head of Electrical Engineering at project A&C.

What he is talking about are solutions that combine several gripper types. “Integrating these intelligently in an overall solution is the real challenge! An example could be an empty pallet gripper or interim layer gripper”. The different grippers need to be all-rounders that can go beyond their own gripping task and simultaneously tackle a number of important functions!

And that’s just two from a whole range of examples! We would be more than happy to making you benefit from our expertise in the development of grippers and so making your automation projects more efficient. Please contact Managing Director Ingo Rathmann and his team at info@project-ac.de.